Digital business strategy – Building an IoT platform

Considering large benefits to be gained, many companies decide to embrace IoT full-front and set out to build their own in-house solution. Their strategy is guided by the notion that the revenues coming from their new digital services will become too great to share, and that a closed digital transformation is essential to their machine building business. The decision to build rather than buy is happily reinforced by the marketing teams of large public cloud suppliers because they want their share of what they view as a potentially large and lucrative business.

This is flawed logic because there’s a large gap between building advanced machines and delivering IoT services.

- Building an IoT platform from scratch increases the time to market, thus affecting the trust of your target market. The best, established IoT platforms in the market have accrued over 10-15 years of development.

- IoT projects are multifaceted and complex as it involves comprehensive constructing means onto hardware, domain expertise in industrial process, expertise in machine learning, software developing and programming competencies, while security and privacy requirements loom large and varying from country to country. In order to deliver a world-leading IoT solution, you need world-leading expertise in all these areas. Do you?

- Until you do a few extensive IoT implementations, you may not know all the probable difficulties in time and ways to escape them. And once the IoT platform is built, it also demands on-going maintenance as it needs to scale across product volume and portfolio.

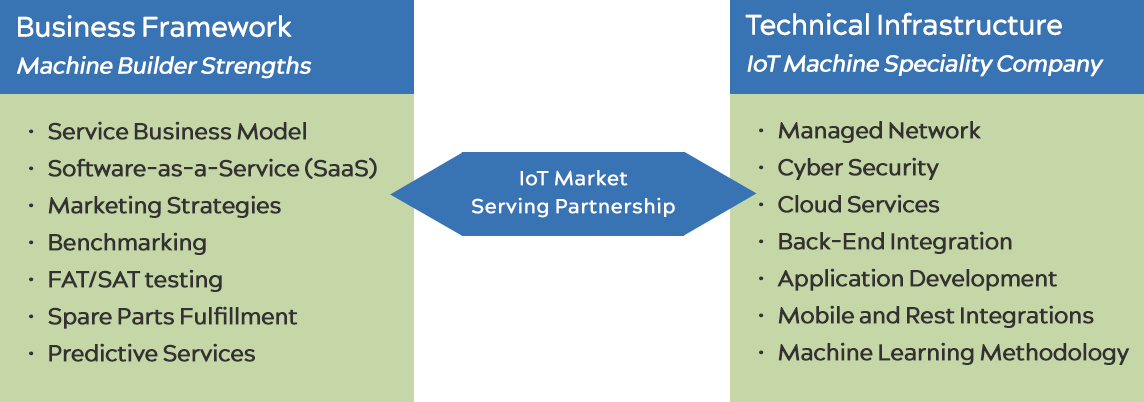

Components to a digital strategy

ei3's IoT Solution

First advantage winners can reduce risk and buy time to market by using ei3’s No-Code IoT platform, tried and tested by leading OEM’s around the world since 1999. ei3 delivers a brand-labeled complete solution that is ready to put best practices to work on your equipment from day one. By providing a true multi-tenant SaaS (Software-as-a-Service) solution, ei3 delivers value and performance right out of the box. The companies that subscribe to ei3’s SaaS save time, save money, stay current, and – most importantly – focus their attention on accelerating their digital offerings to stay ahead of the competition.

Our approach and methodology

By focusing on the common needs of machines in different industries, ei3 delivers a suite of SaaS apps that deliver value without any custom programming. For example:

- Any machine can benefit from having a secure link provide remote service access to controllers.

- Every machine owner appreciates being offered a way to capture and compute OEE and then benchmark and compare machine performance across an entire fleet.

- Predicting parts or consumable needs by dynamically setting and alerting on predictive limits creates value for machine owners and builders.

The custom needs of each machine in its own industry can be easily added to the ei3 offer by using a wide range of extension methods.

Deliver a digital strategy now by using ei3’s secure, robust, mature, and market-tested IoT solution. ei3 understands the importance of your brand and the value it brings to your machine owning customers. By adding our technical craft to your digital vision, you will capture IoT opportunities right away.