Maintain Control and Competitiveness

Our mission is to revolutionize industrial manufacturing with custom-made AI solutions. By using the power of our unique ConnectedAI technology, we equip manufacturers with the tools and insights needed to radically improve machine performance and efficiency, cut expenses, reduce waste, and eliminate unexpected downtime.

Our success is rooted in a collaborative approach, merging advanced AI and data science with deep industrial machinery expertise. Our team of expert data scientists work closely with your engineering team to create solutions, finely tuned to tackle your specific challenges head-on.

Choose us for a high-return, low-risk partnership that not only keeps you competitive on the global stage but also boosts your environmental sustainability and empowers your workforce to focus on what they do best.

Act Now or Miss out

AI will boost production by 10-15% and EBITDA by 4-5%, creating USD 1 trillion in manufacturing by 2030 – but adoption is still in its infancy. Read more >

The future is AI, with 93% of surveyed CIO likely to implement AI/ML tech by 2025 – but many lack a coherent vision. Read more >

ConnectedAI embeds a scientific approach to AI within a comprehensive roadmap, delivering benefits to all organizational levels to fully embrace digitalization.

A staggering 93% of manufacturing companies anticipate growth and innovation through AI, however only 9% believe their AI projects will meet expectations. Read more >

You Are in Good Company

TRUST. EFFICIENCY. SUCCESS.

READ ABOUT SOME OF OUR PROJECTS

AI That’s Personalized for Your Success

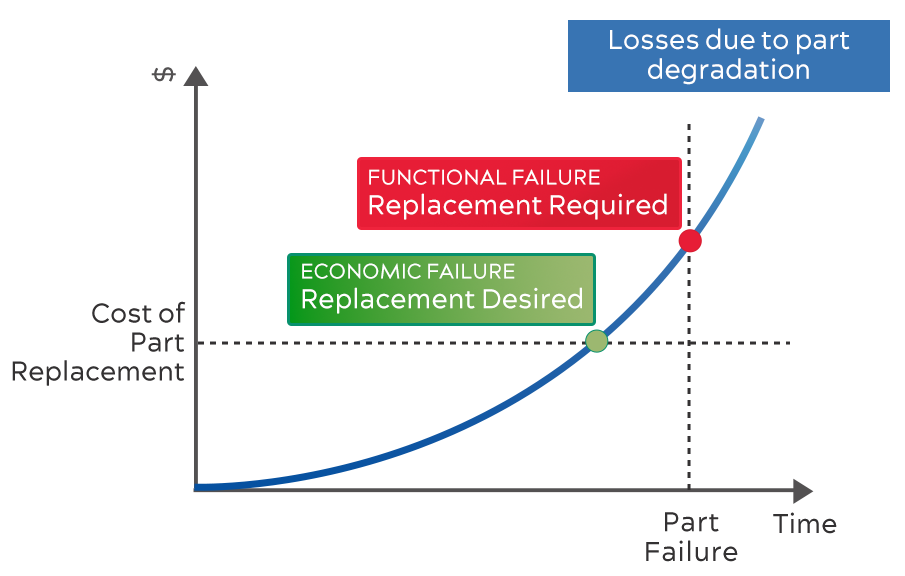

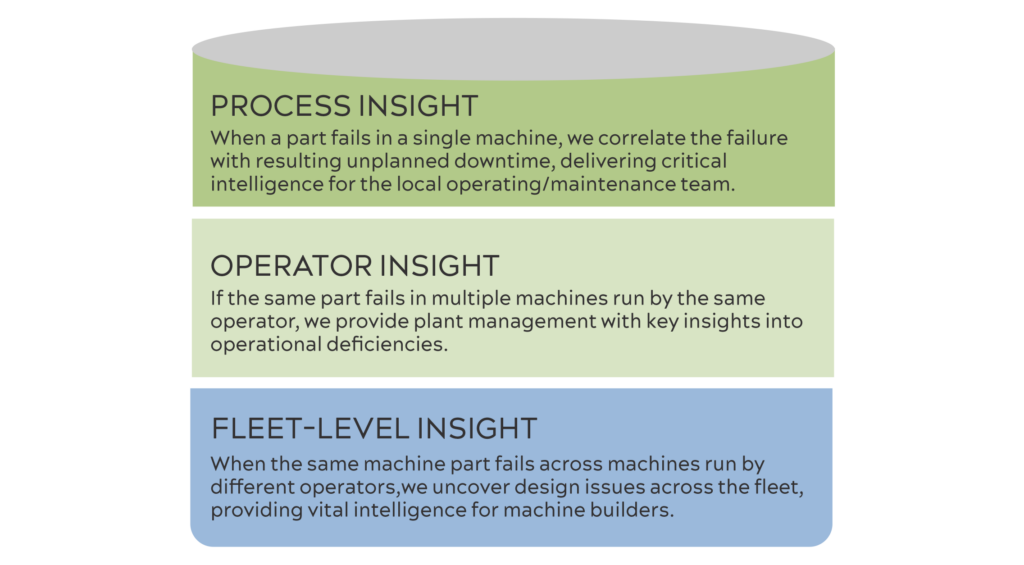

ConnectedAI predicts what matters. This is not just “predicting when machines will fail”. Our unique approach is based on continuously understanding and quantifying the wear and tear that impacts your machines – and advising how to maintain machine operations at their best.

The best time to replace a part is not when it is about to fail, but when the impact of its degradation outweighs the cost of its replacement.

With ConnectedAI, every part of the manufacturing organization gains valuable insights, ensuring peak efficiency and cost-effectiveness across the board.

FOR THE

C-SUITE

Get performance metrics across your plants, lines, and crews to stay top of what is happening and what is changing.

FOR THE

SUPERVISORS

Assess asset profitability, predict delivery issues, and get cost-effective maintenance recommendations.

FOR THE

PRODUCTION STAFF

What Sets ConnectedAI Apart?

ConnectedAI is integrated into the ei3 IoT suite – the manufacturing industry’s trusted IoT provider since 1999. We establish secure connections with thousands of industrial machines worldwide, ensuring reliable data collection and analysis.

What distinguishes us includes:

- A Structured Methodology with an Emphasis on Early Go/No-Go Decisions

- Expertise in Big Data Analytics

- Utilization of Federated Learning

- Implementation of Learning Twins

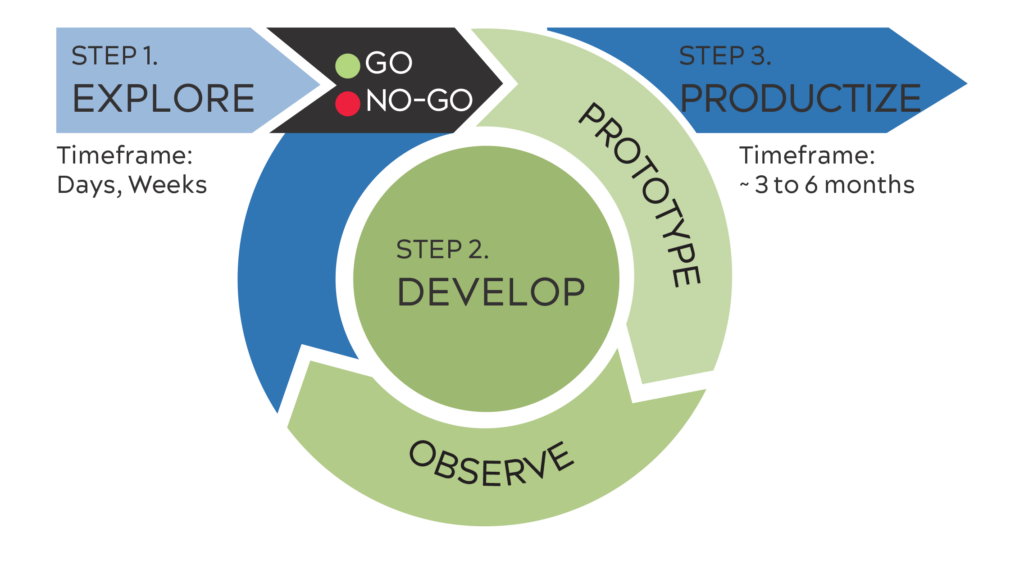

1. EARLY GO/NO-GO DECISION

Our structured methodology focuses on an “Early Go/No-Go” decision and an agile development approach that delivers increasingly sophisticated insights quickly.

By adopting this strategy, we steer clear of expensive and prolonged data science projects that lack a clear ROI.

2. BIG DATA ANALYTICS

Our analytics is based on aggregated knowledge across different operational domains to accurately assess the significance of data and achieve improvements beyond event-based data processing.

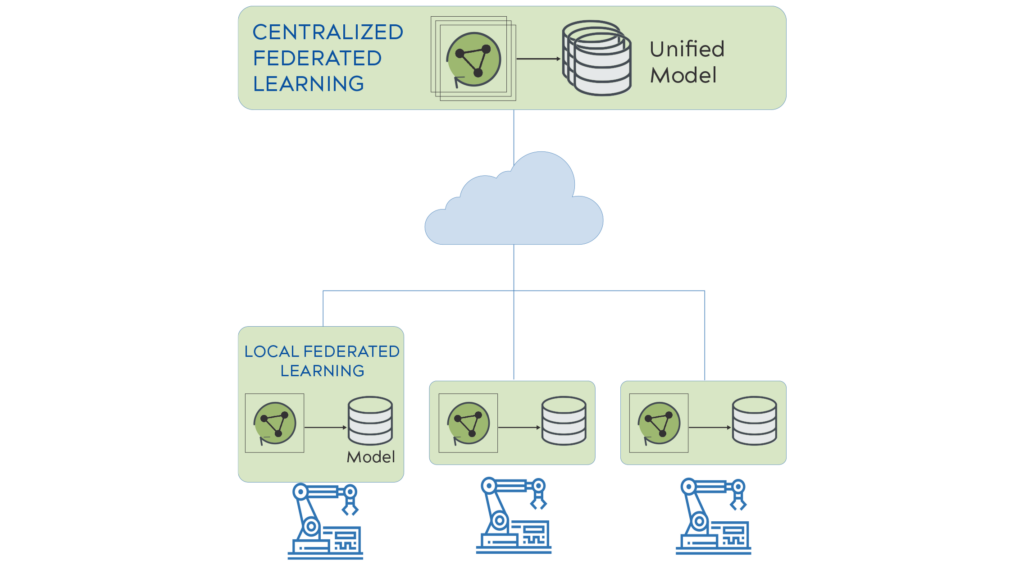

3. FEDERATION LEARNING

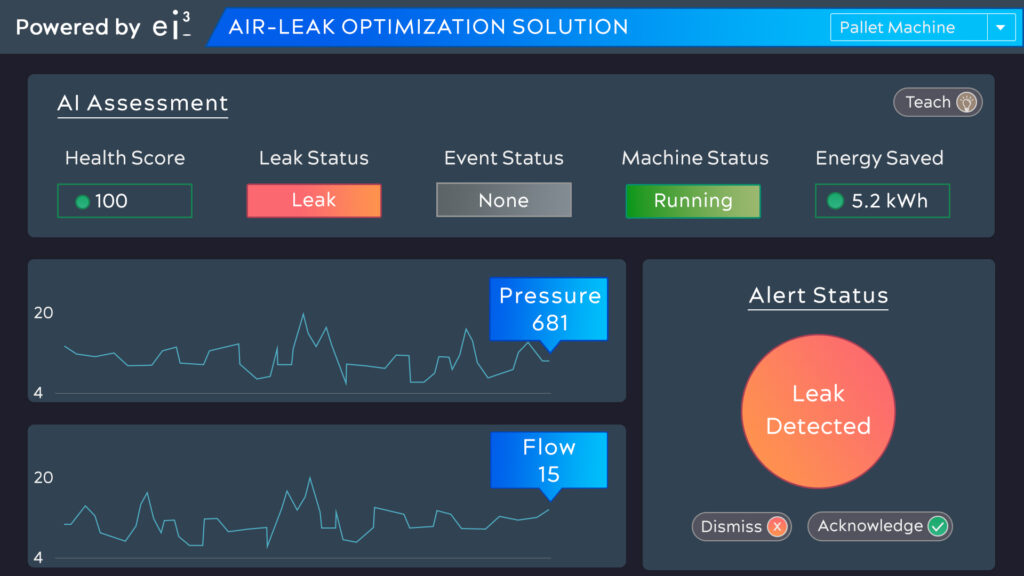

ConnectedAI implements federated learning that uses a mixture of local data analytics – on each machine – and centralized analysis. This maintains the privacy of data – we do not need to collect all data to analyze it! – yet still allows fast, fleet-wide learning.

4. LEARNING TWINS

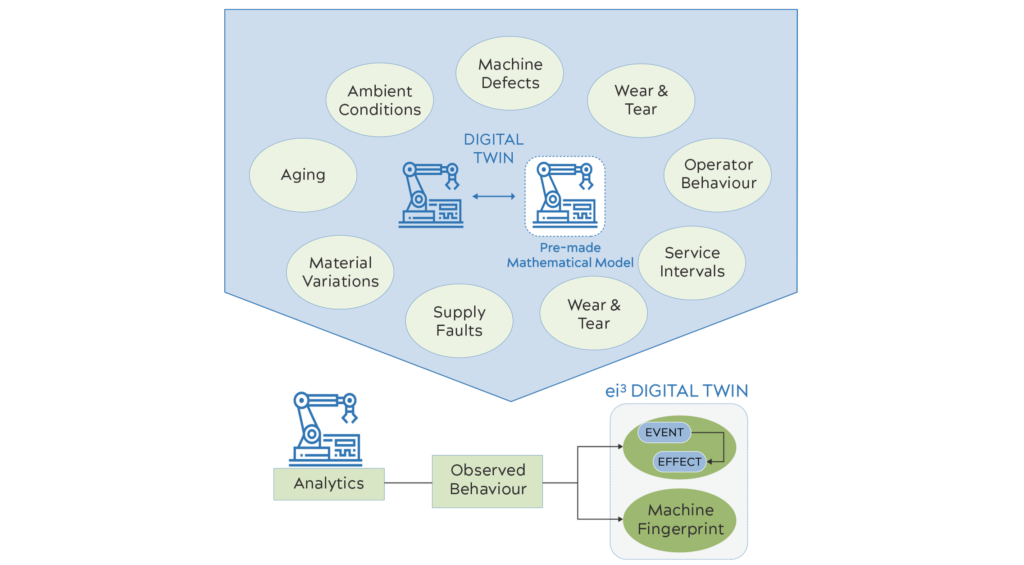

ConnectedAI is based on extensive observation of machine- and process data. Insights are based on continuously detecting, observing, and recording changes to behavior – not simply comparing data to a mathematical model such as a “Digital Twin”

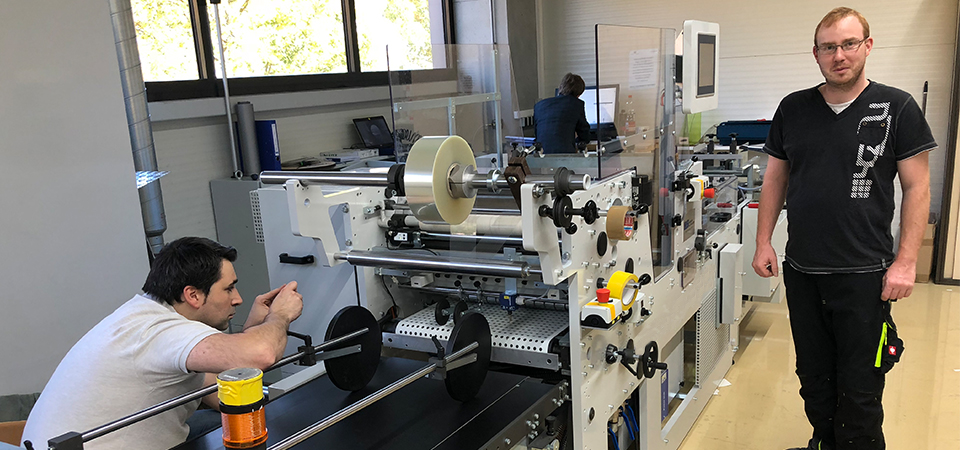

Meet Our Champions:

The People Powering Our Cutting-Edge Technology

ei3’s Zurich-based Data Science Center stands as a beacon of innovation, founded by experts with over 20 years of experience in delivering robust data analytics for the manufacturing sector. In collaboration with premier research institutions like ETH Zurich and the University of Cambridge, we’re at the forefront of merging theoretical knowledge with industry application.

Our team’s unique combination of technical expertise and practical know-how is the cornerstone of our success, transforming complex algorithms into accessible, operator-friendly solutions that enhance efficiency for plant managers and technicians. This approach helps our clients remain competitive in the global market, boosts environmental sustainability, and lets operators and users focus on what truly matters.

Anticipating some common client inquiries with these FAQs:

Data Science can solve many problems that plague industrial manufacturers. Modern machines – and even old ones! – create large amounts of data as they operate. Mathematical algorithms developed by data scientists can look for anomalies in that data to pinpoint irregularities. These can be caused by wear and tear, incorrect machine settings or setups, or operator errors. Many of our clients use our algorithms to continuously optimize their machine operations to increase machine efficiency, reduce cost or waste, reduce energy consumption, detect and avoid operator errors, or implement condition- or predictive maintenance strategies.

Our clients typically approach us with specific business issues that need to be addressed – a pain point. This can be perceived shortfalls in machine efficiency or productivity, higher than needed energy consumption, waste, or product rejects, repeated machine failures, or the desire to anticipate and avoid unplanned downtime.

Based on this pain point our data science team will engage with the client to develop a solution approach based on a data-science hypothesis. In other words, we will jointly with the client develop a strategy to solve the issue using the data and tools available from the client.

Before engaging on a full scale project we will usually conduct a short term study to efficiently proof, or dis-proof, that the hypothesis can be substantiated with data. This avoids long and expensive exploratory projects and avoids disappointment if the hypothesis turns out to be incorrect. Our projects deliver success efficiently – or fail very quickly.

Data cleaning usually starts with the identification of the most important dimensions, which sufficiently describe the processes that should be modeled. Once these dimensions, or features are selected, the second step will be to ensure that the data make sense, by removing any duplicate columns, deleting irrelevant data, removing statistical outliers and filling missing values.

Every data science algorithm is tailored to a specific type of problem. Given the available data, we choose and adapt the most appropriate one.

Projects are designed for seamless integration into existing systems. Hence the API approach is usually chosen so that the existing systems can send requests to the data science systems, which allow those to not necessarily have to be on the same physical systems.

ei3 operates its own private world wide network of data centers and through it provides IIoT data collection and IIoT services with unparalleled reliability, safety, and security. ei3 can host any data science algorithm for any client on that network.

Our clients are also free to use their own hosting environments to implement any data science algorithm on their own, or existing, IT infrastructure, or directly on their machines.

Data science projects usually start with a Pilot, in which we explore the data for the project. Insights of this phase helps define a timeline of the overall project. Project durations can vary, ranging from a few weeks to several months.

The Data Science team engages through different business models. We offer hours-based consulting and data science services, or fixed-price contracts. Talk to us to find out what might be appropriate for your project!