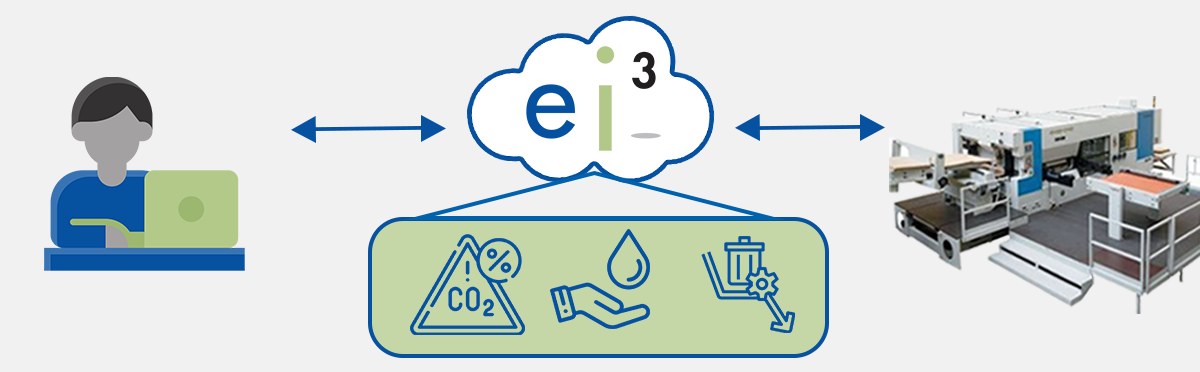

By monitoring the converting plant floor equipment’s consumption of resources and production results, it is possible to accurately describe the sustainability impact of the converting stage of the packaging life cycle. ei3’s remote monitoring server provides enterprises with an effective method for gathering, storing, analyzing, and reporting the sustainability of packaging processes. Having this information available promotes a more transparent supply chain and helps enterprises comply with a growing need for collaboration to promote sustainability.

Consumers and other stakeholders look to brand owners for information about the packaging of their products. This need for information is prompting the use of scorecards and labels that describe the sustainability of a package. But making an accurate label is challenging because in many cases, the brand owners don’t have all the data. To close this gap, there needs to be a transparent sharing of data from the converting suppliers to their brand customers. The data may not currently exist, making it challenging for converters to provide accurate reports that quantify energy use, water use, carbon footprint, waste, and other aspects of the package.

ei3 has a proven solution that nicely meets the requirement of providing this important data. The ei3 remote monitoring Cloud can collect, store, analyze, display, and report on the sustainability of packaging materials in the converting plant. It works by performing real-time remote monitoring to measure the energy consumption and packaging units of production on a per-machine and per-building basis. This data provides users with the information needed to provide end customers with an accurate sustainability report.

The role of measurement

The Sustainable Packaging Coalition (SPC) is an industry working group dedicated to a more robust environmental vision for packaging. The SPC makes available a broad range of publications and resources to further the vision and ever-evolving implementation of sustainable packaging. One of their publications, the “Sustainable Packaging Indicators and Metrics Framework” (available for download from their site), provides a set of common indicators and metrics to help companies measure progress against the criteria articulated in the SPC’s definition of Sustainable Packaging. The framework covers all aspects of packaging, the “Cradle to Cradle” approach. This approach is enabled by summing up the impacts in all the stages, each stage being a “gate-to-gate,” or sometimes a “cradle-to-gate.”

At the converting stage of the packaging life-cycle, using a gate-to-gate approach, there are a number of measurements that can be obtained to meet the requirements of this framework. Specific examples include material used, % yield, energy used, water used, all normalized by the per-production-unit, e.g. pounds, ft2, or other. Having an accurate report detailing the quantitative measurements of these items completes an important part of the overall analysis. Converting is an important step in the package creation process with many opportunities for energy reduction coming from various manufacturing methods and equipment types.

Gather data from the plant floor

ei3’s remote monitoring cloud server gathers data from the plant floor using established industrial device communication standards and securely transports the data through the internet to a cloud application. The ei3 method builds upon the capability of existing infrastructure already in place. Consider that most plant floor equipment that has been installed within the past 25 years already has the requisite electronic controllers and these controllers know most of the key production values of the machines. By tapping into these existing controllers (using standard communications hardware and software), the ei3 remote monitoring Cloud server can record production and all the machine related parameters.

The ei3 remote monitoring Cloud does not interfere with the existing devices controlling equipment. In fact, the ei3 server uses the same data collection methods that are deployed by most in-house data collection computer applications. The only difference being that the data is securely transported to our world-class data centers for storage, analysis, visualization, and reporting. Sometimes it is necessary to add additional electricity, gas, or water measuring devices to get a complete picture of the machine’s, and consequently the product’s sustainability profile. These sensors can be easily added and integrated into the ei3 remote monitoring Cloud. Additionally, the building that holds the machine should also have its utilities monitored to gather the necessary data for calculating a weather-normalized per square foot energy use index.

Analyze the data

Once the machine data has been accumulated the various components of production need to be applied to the actual final converted product. Many converting plants hold equipment that performs different operations on materials to create a complex final product; for example printing, then die-cutting, then folding & gluing. As the production runs through each of these stages, the energy intensity is increased in direct proportion to the amount of energy used by the machine. Once the product has been processed by all the converting operations, then the product’s energy index is known as the sum of the various stages. This index takes into account the space the machines occupy and the time the material is in the warehouse.

The ei3 remote monitoring cloud does not interfere with the existing devices controlling equipment. In fact, the ei3 server uses the same data collection methods that are deployed by most in-house data collection computer applications. The only difference being that the data is securely transported to our world-class data centers for storage, analysis, visualization, and reporting. Sometimes it is necessary to add additional electricity, gas, or water measuring devices to get a complete picture of the machine’s, and consequently the product’s sustainability profile. These sensors can be easily added and integrated into the ei3 remote monitoring Cloud. Additionally, the building that holds the machine should also have its utilities monitored to gather the necessary data for calculating a weather-normalized per square foot energy use index.

Compute packaging material energy intensity

(Machine Energy Use + Building Energy Use + Other Energy Use) / Production Yield = Converting Stage Packaging Product Energy Use Intensity

Benchmarking can be done to compare a product’s energy intensity across machines and facilities. Knowing the baseline value for a product’s energy intensity, it is possible to gain a better understanding of an operation and consequently work towards optimization. Dashboards and reports that show the relative energy intensity for similar products run at different facilities or on different machines enable organizations to use Sustainability as a tool to optimize their production planning.

Provide transparent reporting to the supply chain

The Global Packaging Project, started in 2009, was chartered to: 1) define packaging’s role in sustainability, 2) agree on common language/terminology to discuss packaging sustainability across the supply chain; and 3) develop a standard set of metrics by which to measure packaging sustainability over its full life cycle. The goal of the project is to ensure that 1) requests for data related to the sustainability of packaging are made using a common set of indicators and metrics and 2) the requested data is collected, normalized, and delivered according to a common set of standards and protocols affiliated with each indicator and metric.

The ei3 remote monitoring cloud provides converters with a way to comply with the requests for data regarding sustainable packaging. Ultimately the sustainability report might be somewhat similar to other reports made by ei3’s remote monitoring cloud, for example, the “Certificates of Analysis”. The COA report is a quality document that is based on machine performance and quality data, the data is gathered by ei3’s remote monitoring cloud and then compiled and sent to the appropriate end-customer on behalf of the converter. This cloud-based delivery method saves time and money while at the same time provided both parties with the assurance of accurate data.

Providing measurement of sustainability data throughout the supply chain is best handled by a Cloud computing application. Because within the converting stage, there are many points that are best accumulated through automatic measurement. A remote monitoring cloud holds the promise of gathering and analyzing the data in a way that promotes accuracy, eliminates the need for additional staff hours to accumulate, and takes advantage of the collaboration features typical of an internet application. ei3 Corporation has been delivering its remote monitoring cloud and tracking dustainability for more than 12 years and has a platform in place that not only meets today’s needs but delivers on the commitment of meeting the sustainability challenges of tomorrow.